How Should HVAC Systems Respond to Airborne COVID-19?

From FacilitiesNet.com and American Ultraviolet, https://www.americanultraviolet.com/

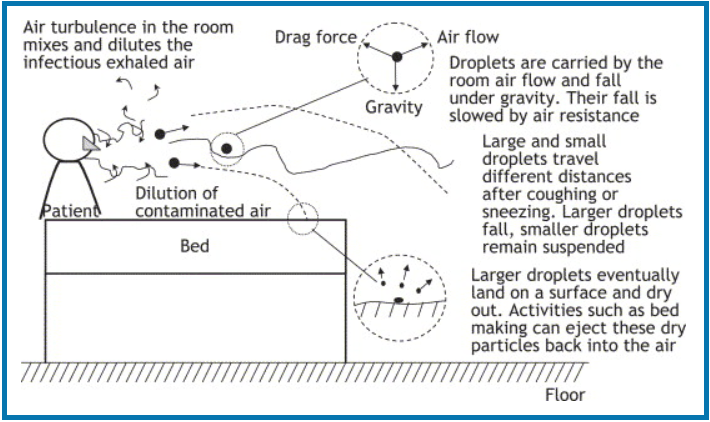

In response to the coronavirus pandemic, it is no longer sufficient to focus germicidal disinfection efforts exclusively on sanitizing surfaces.

Since airborne transmission is a significant factor in the spread of COVID-19, in order to remove harmful microorganisms from the air stream you need the addition of UVC light for germicidal irradiation of the pathogens.

For more than 70 years, tens of thousands have been safely installed in hospitals, clinics, processing plants, offices, manufacturing sites and other commercial facilities.

From the American Society of Heating, Refrigerating and Air-Conditioning Engineers

ASHRAE Statement on airborne transmission of SARS-CoV-2: “Transmission of SARS-CoV-2 through the air is sufficiently likely that airborne exposure to the virus should be controlled. Changes to building operations, including the operation of heating, ventilating, and air-conditioning systems can reduce airborne exposures.”

From the EPA Coronavirus COVID-19 Website

https://www.epa.gov/coronavirus/indoor-air-and-coronavirus-covid-19

“Although improvements to ventilation and air cleaning cannot on their own eliminate the risk of airborne transmission of the SARS-CoV-2 virus, EPA recommends precautions to reduce the potential for airborne transmission of the virus.”

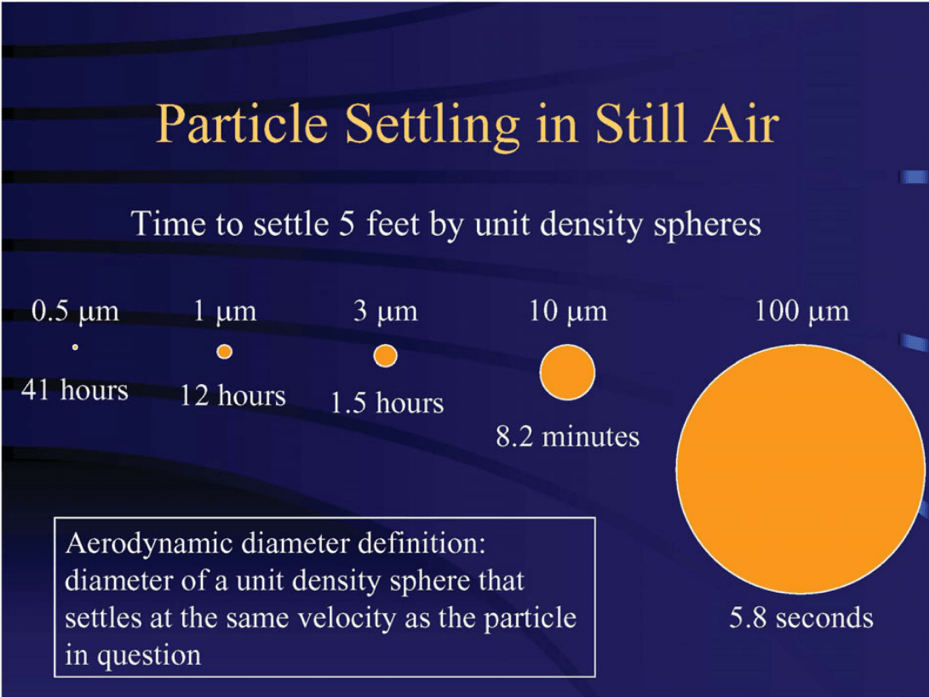

The images below (from ASHRAE) depict the time that particles can linger in air before settling to a surface.

As a reference, the diameter of COVID-19 ranges from 0.06 to 0.14 μm.

Smaller, lighter particles (like COVID-19) have the potential to remain airborne for hours, during which they can be transported large distances by building heating and cooling systems.

HVAC Air Duct System – UVC Germicidal Fixtures

On-Coil Surface Disinfection (CC Series)

High-output CC Series HVAC UV light fixtures are designed specifically as HVAC air cleaner systems. They can be mounted in various configurations for optimum pass-by UV air sterilization and/or to irradiate cooling coils and drain pans. These individual HVAC UV air purifiers can be mounted to frame assemblies that span supply ducts or cooling coils.

CC Series fixtures are offered as single and double lamp configurations with “moisture proof” construction. They may be mounted individually; in built-up banks; or in parallel rack-system configurations in a variety of locations, including coils, drain pans, ductwork, mixed air plenums and exhaust systems. The CC Series is available in five lengths (18”, 24”, 36”, 48”, and 60”) and four voltage options (115, 208, 230, or 277 VAC), providing installation flexibility to accommodate virtually any system.

HVAC Air Cleaner Benefits

- Improves Indoor Air Quality (IAQ) by reducing bacteria, viruses and mold that either grow or pass through the air handling systems

- Reduces the risk of cold, flu, allergies and other illnesses associated with air handling systems

- “Green” lamps contain less than or equal to 8mg of mercury

- Two-year gaunter on lamps with only 20% decrease in output over two years

- Five-year, non-prorated warranty on the ballast

- Continuously clean coils, drain pans, plenums and ducts, eliminating costly cleaning programs and the use of harmful chemicals and disinfectants

- Reduces HVAC energy costs by restoring heat transfer and net cooling capacity

- Produces no ozone or other secondary contaminants

- Plug-in connections mean no field wiring required to connect fixture to picture when building banks of rack systems (except for 277 Volt applications)

HVAC Air Duct System - UVC Germicidal Fixtures

In-Duct Air Disinfection (DC Series)

American Ultraviolet High-output DC Series HVAC UVC germicidal fixtures can be mounted in various configurations for optimum pass-by air decontamination and/or to irradiate cooling coils and drain pans. Lamps and electronics can be accessed from outside the duct or plenum. “Green” lamps (contain 20mg of mercury) extend inside to span supply ducts and/or cooling coils.

American Ultraviolet DC Series Benefits

- Improves Indoor Air Quality (IAQ) by serving as a UV-C air sanitizer, reducing bacteria, viruses and mold that either grow or pass through the air handling systems. Reduces the risk of cold, flu, allergies and other illness associated with air handling systems

- “Green” lamps contain = 8mg of mercury

- Two-year guarantee on lamps with only 20% decrease in output over two years

- Five-year, non-prorated warranty on the ballast

- Continuously cleans coils, drain pans, plenums and outs, eliminating costly cleaning programs and the use of harmful chemicals and disinfectants

- Reduces HVAC energy costs by restoring heat transfer and net cooling capacity

- Produces no ozone or other secondary contaminants

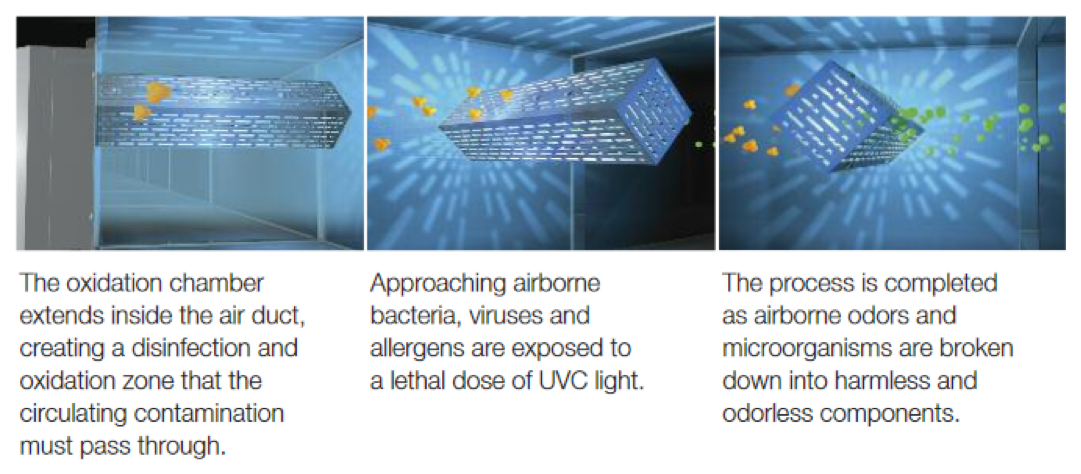

UVPhotoMAX™ uses the power of UV light and an exclusive photocatalytic process to react with and destroy millions of bacteria, viruses, and allergens in the air circulating through your HVAC system.

The UVPhotoMAX takes Photocatalytic Oxidation (PCO) air purification to a new level of convenience and effectiveness.

TVA EnergyRight Business & Industry / Incentives / Ultraviolet germicidal irradiation

TVA is offering Incentives for Ultraviolet Germicidal Irradiation deployments in HVAC systems

Conventional UV-C lamps can be installed inside ductwork to disinfect moving air on every pass through a school, hospital, or commercial building of any sort.

TVA is offering standard incentives for duct-mounted UVGI systems, amounting to $30 per ton toward the purchase and installation of UVGI in your facility’s HVAC ductwork system.

Per the American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE), UVGI systems must deliver a sufficient dose of UV-C rays to inactivate airborne microorganisms within a 2 ft (0.6 m) minimum irradiation zone down the length of the duct or plenum, providing roughly 0.4 seconds of exposure time in moving air. An irradiation level, Ultraviolet Rating Value (URV) of 13 is the minimum recommended UV intensity level to deliver a sufficient dose to inactivate airborne microorganisms. Properly designed high-intensity systems can achieve 95% disinfection rates.