Farmers Co-Op

Energy Efficiency Project

LED Lighting - Energy Management Solutions, Murfreesboro, TN

HVAC Optimization - Thermal Dynamics, Brentwood, TN

The Tennessee Farmers Co-Op Headquarters in La Vergne, TN is a federated farm supply cooperative that serves 164 Co-Op Retail Outlets throughout Tennessee. During our multi-year project, we installed Eaton VFDs and an Energy Control System at the Main Office Building, and converted most of the Co-Op Campus buildings to LED technology.

VFDs were installed on HVAC system components (return fan, pumps, air handlers). A total of 2,126 lights were replaced with LED fixtures or retrofitted with LED tubes and bulbs.

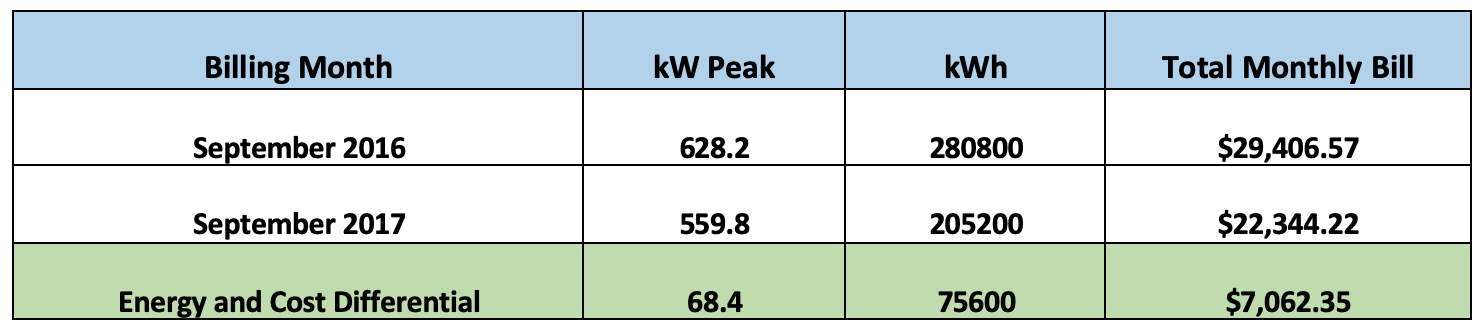

From September 2016 to September 2019, kW was decreased by 23% and kWh was decreased by 44%.

LED Lighting Upgrade

A total of 2,126 lights were replaced with LED fixtures or retrofitted with LED tubes and bulbs.

We replaced fluorescent and Metal Halide fixtures with Arcadia LED highbays, reducing wattages from 400w to 88w in some instances. The majority of these LED highbays were equipped with Motion Sensors. All installed fixtures were 5000K and 13,000 to 22,000 lumens.

We retrofitted office troffers and fluorescent strips with 5000K, DLC Premium T8 LED tubes, bypassing the ballast. We used Energy Focus Flicker Free lamps with a 10-year warranty.

We replaced pole lights with 150w LED fixtures (5000K and 22,000 lumens), and re-lamped a variety of wall packs and outdoor lights with 17w and 40w 5000K LED bulbs, using product from Arrlux and Horner.

Changes in Energy Consumption and Cost over the first 12-month period

HVAC Optimization

In the 53,000 square foot Main Office are two HVAC chilled water systems:

#1 includes a 90-ton Carrier air-cooled chiller with a chilled water pump (7.5HP), three constant volume air handlers (7.5HP, 5HP, 15HP), and an accompanying return fan (1.5HP).

#2 includes a 60-ton air-cooled chiller with a constant GPM chilled water pump (5HP) and one constant volume air handler (25HP).

We installed Eaton variable speed drives (VFDs) on all the above designated items, and an Energy Control System. A central controller resides wirelessly on the customer’s internet router, enabling remote access and communication with the VFDs via a Modbus network.

VFDs, when added to constant volume air handling fans, create a hybrid variable volume air handler system. Fan VFDs operate at full speed when the outside air temperature is at or near summertime design conditions. The speed is reduced via an algorithm as the outside air temperature reduces throughout the year. This saves energy and improves dehumidification.

The Energy Control System includes an Unoccupied Off status on a daily and weekend schedule. During Unoccupied Off, air handlers are off, but start hourly to create air flow to monitor room temp, and change to Unoccupied On status if the room temperature rises above 80 or below 60. AHU’s run at 50% speed during this condition.

CHWP-1,2: These pumps reduce speed based on chilled water supply and return water temperature differential.

Sensor inputs: Supply Water Temperature, Return Water Temperature.

AHU-1,2,3,4: Air Handlers reduce speed as outside air temperature falls.

Sensor Inputs: Outside Air Temperature (provided by an API from a weather website and updated every 3 minutes), Room Air Temperature.

RF-4: Return fan associated with AHU-4

Return fan to track AHU-4 at the same speed output less 5%

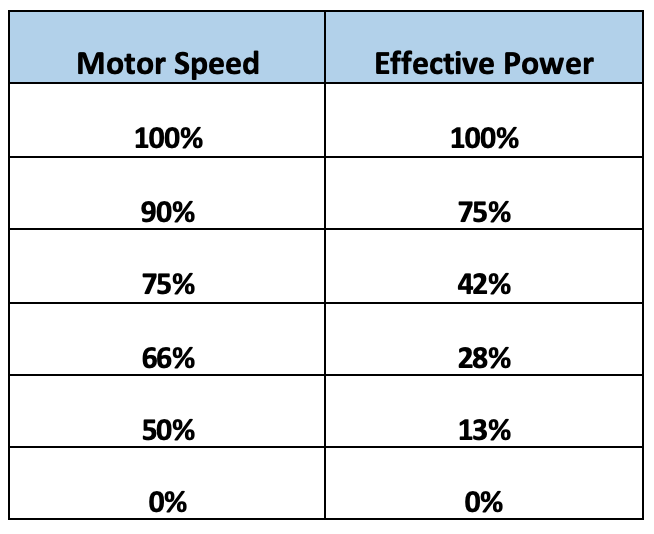

The chart below depicts how the required power is decreased dramatically as the motor speed is reduced, resulting in significant savings.

For example, when the Motor Speed is reduced to 75%, the necessary power decreases to 42%, resulting in a 58% energy savings.